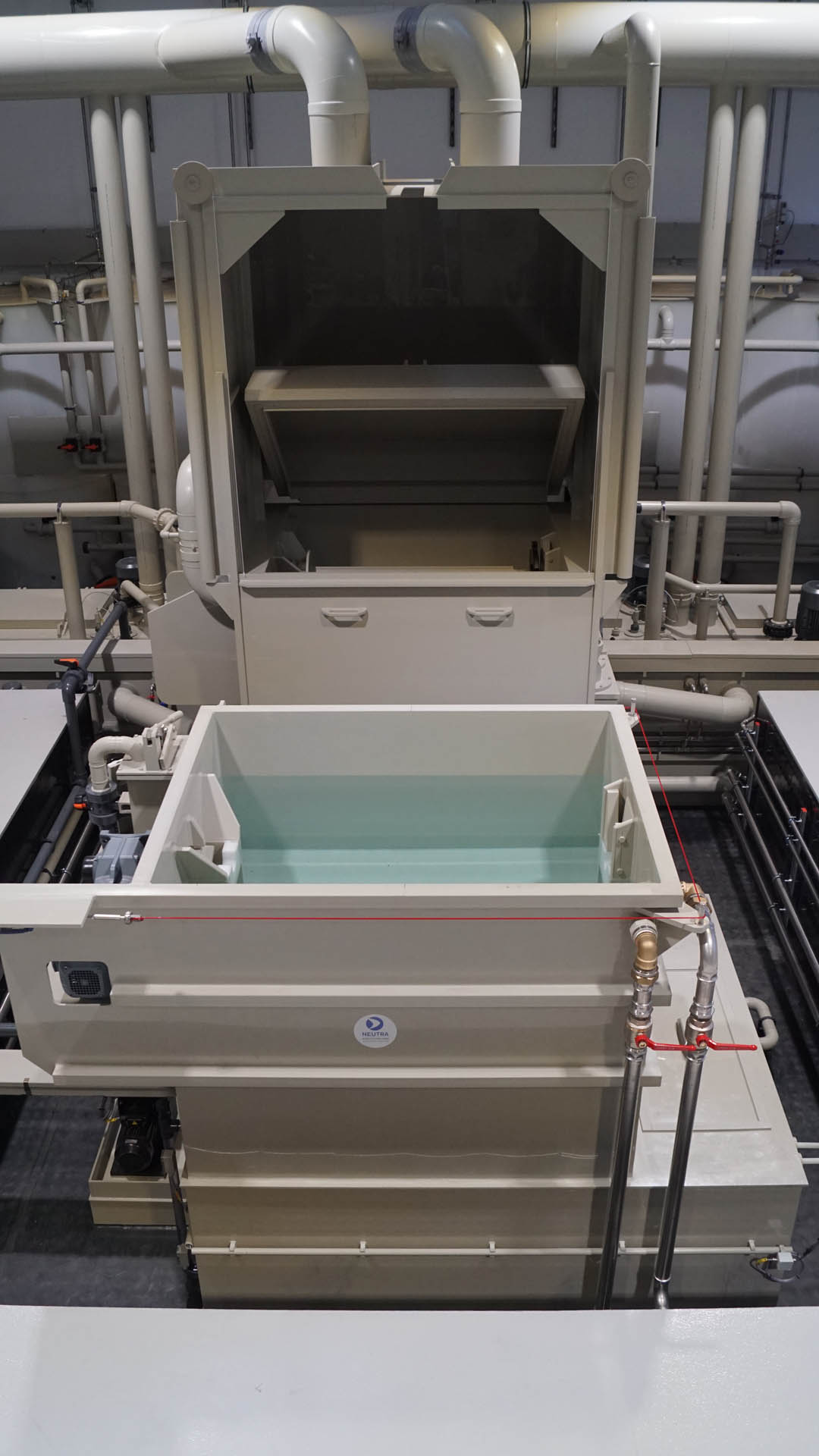

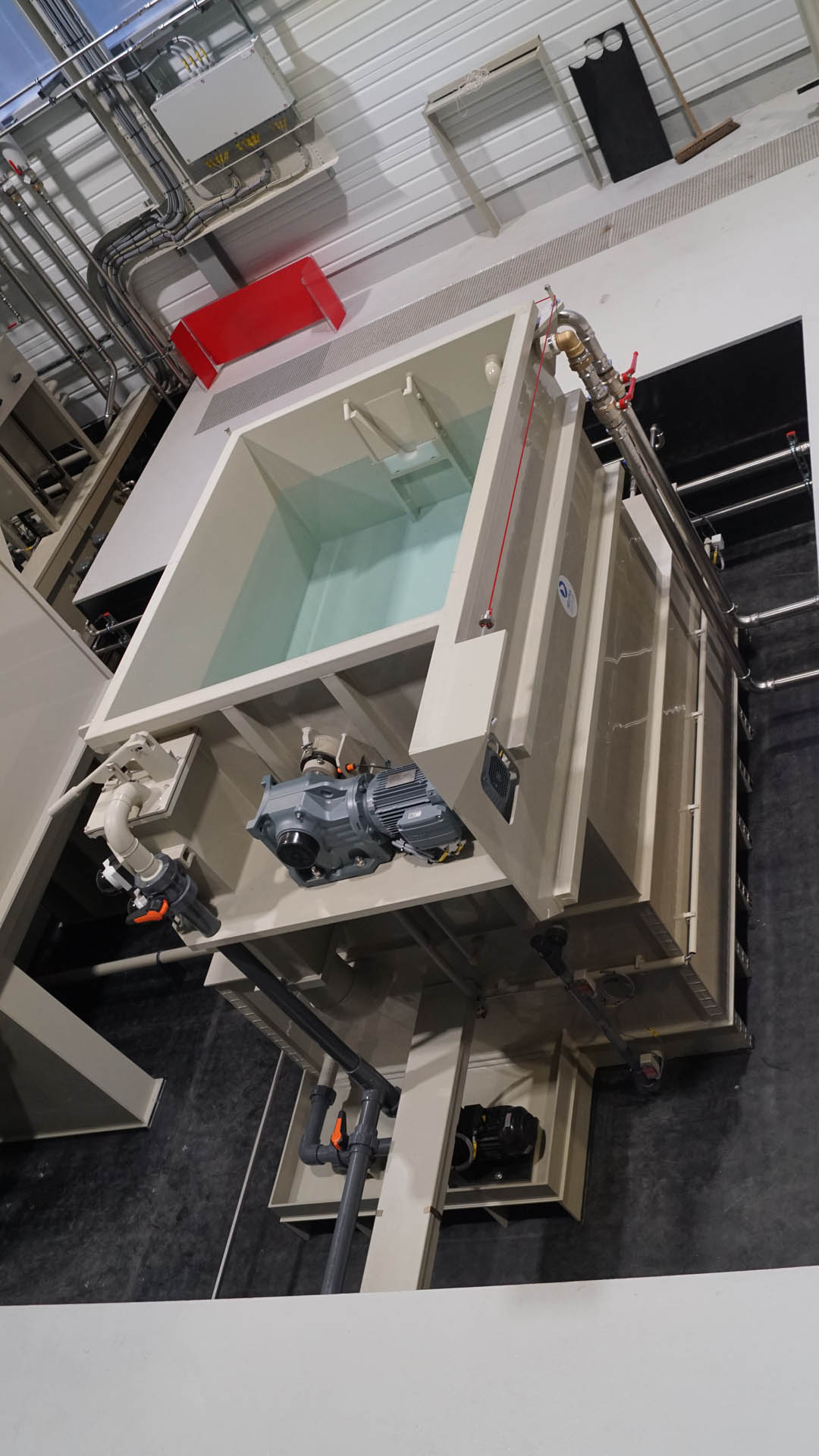

Acid polishing systems for glass

Our acid polishing systems give glass a lustrous, homogeneous surface and, thanks to innovative technology, are not only safe but also represent a low-cost investment. User-friendly in operation, they deliver optimal production results in a short period of time. We also offer services to train personnel in the operation of the systems. State-of-the-art technology and high-quality components maintenance and operating costs many times over.

Advantages of choosing our glass finishing techniques

- Advantages of choosing our glass finishing techniques

- Higher quality than in-fire polishing

- Less expensive than laser processing

- Completely homogeneous and tempered surface

Development and innovation

At Neutra, we constantly strive to further develop and refine our acid polishing systems. The experience we have gained working with leading international customers helps us to advance our proven systems, thereby ensuring technological progress of the highest order.

Neutra offers excellent customer service thanks to its qualified glass engineers, who can train your employees right from the very basics. We continue to accompany and support our customers long after their systems are delivered.

We are your specialist provider for:

- Acid polishing

- Glass acid polishing

- Acid polishing systems

- Acid polishing machines

- Acid polishing technology

- Acid polishing plant

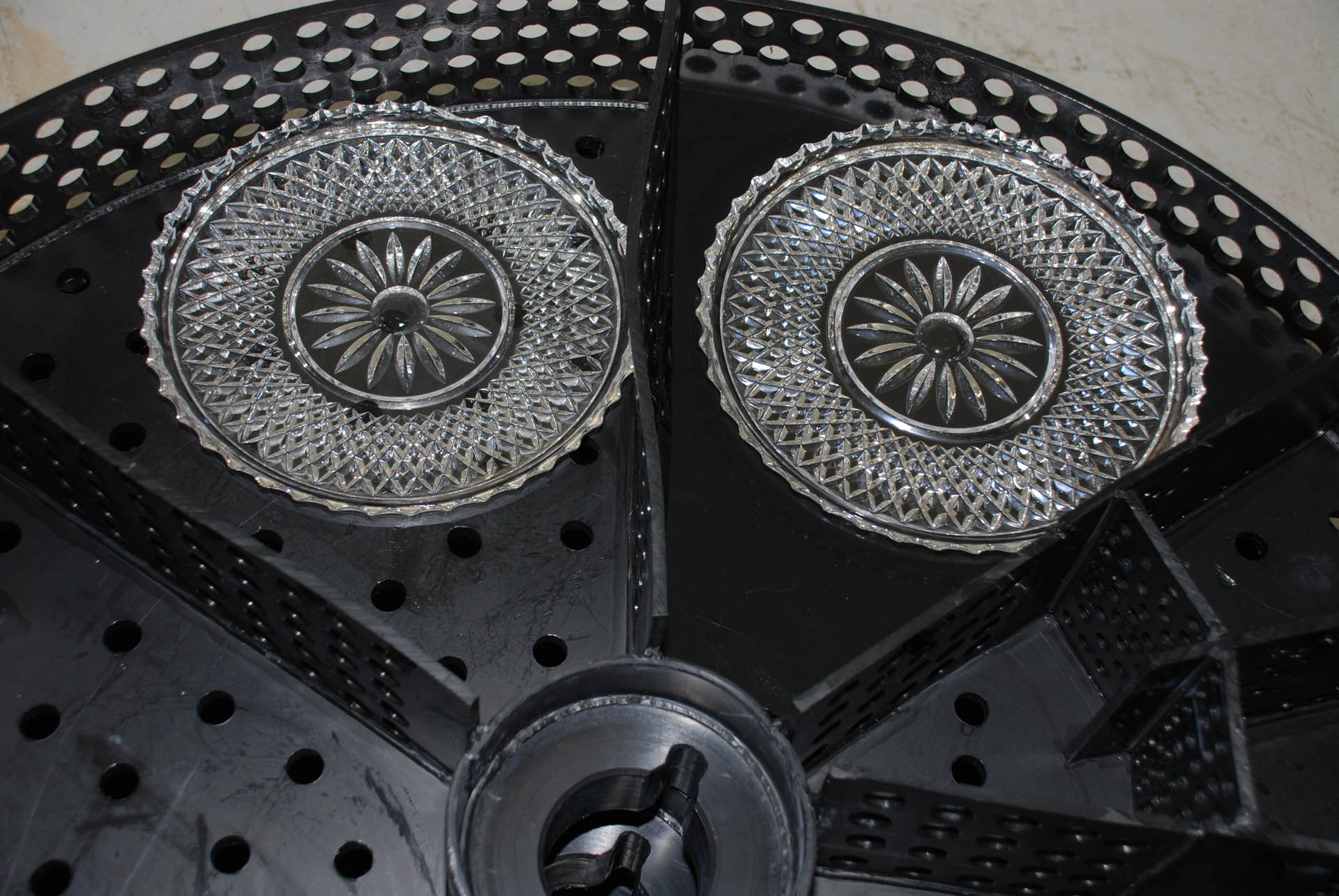

Examples of our developments:

- Flexible polishing programs for different product groups, specially developed according to customer products

- Polishing drum rotational speed adjustment

- Polishing drum rotational direction adjustment

- Automatic acid dosing during the polishing process

- Automatic documentation of settings, which facilitates production monitoring over a given period (e.g. 14 days)

- Creation of an interface to monitor the system from the production manager’s office

Gallery about NEUTRA acid polishing systems:

Contact

Send your query using our contact form or give us a call. We’ll be happy to advise you.